|

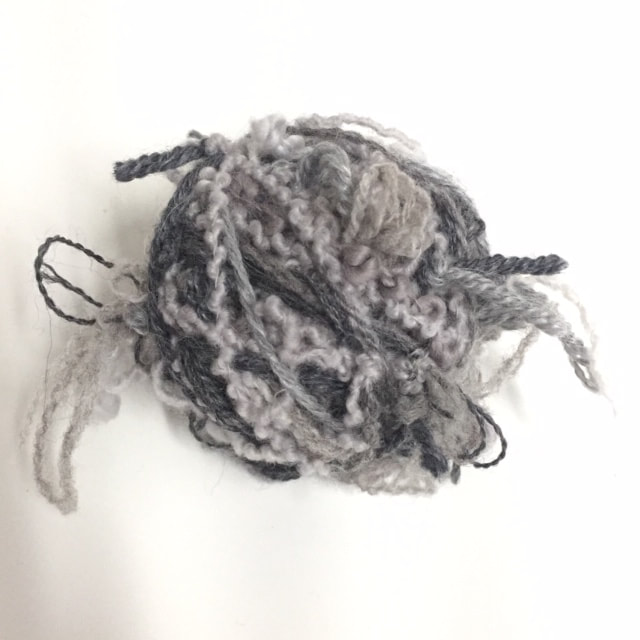

Last weekend, I was having dinner with some of my friends after we had visited the Estes Park Wool Market. I had just purchased a raw fleece, and three of us had recently been gifted with one raw fleece each. The eternal question came up - "Why bother with processing a fleece from start to finish when you can buy lots of really good fiber that's already cleaned and ready to spin?" I was stumped, in part because I didn't have one answer. I had at least ten. There are lots of reasons to process your own fleece, from raw wool to finished yarn. Here are some of mine: 1. To Say You've Done It I tend to have a strong urge to try new things, especially when it comes to fiber arts. Sometimes, having tried a new skill, I can say, "been there, done that, what's next?" That was the urge behind buying my first fleece, and it's a perfectly valid reason to try it. If nothing else, you'll have gained (yet another) post-apocalyptic life skill! 2. It's a Different Part of the Process to Enjoy Wool is the original miracle fiber. It's warm, elastic, durable, resists staining (but takes dye beautifully), breathes well, and is fire resistant. I love the feel of it in my hands, whether it's when I'm spinning, knitting, weaving, felting, or rug hooking. When I buy a raw fleece, I get to extend my enjoyment of the process. 3. Learn More About the Process Every time I process another raw fleece, I learn something new about spinning. How does this sheep's wool behave? What will it look like as yarn? What uses would make it really shine? It also makes me appreciate processes that were a normal part of life for people working with textiles in the pre-industrial era - and it makes me really appreciate my water heater! 4. Learn What to Look For in a Fleece There are plenty of guides that tell you how to buy a fleece, but there's nothing like the experience of following all the advice and then using the wool to see if it's something you like. The more fleeces you process, the easier it will be to look at a raw fleece and make a buying decision! 5. Get Exactly the Fiber Prep You Want There is nothing in the world like fiber that has been hand combed or hand carded well. It is easier and fluffier to spin. You can easily create roving or combed top that fits your own hand, not a thickness that is optimized for industrial production. You can also experiment with combed vs. carded preparations. Some fibers are usually only available as one or the other. What would happen if you did it another way? Combing and carding yourself gives you the opportunity to experiment and see what you like best. 6. Participate in Your Local Fibershed This is a big one! When you buy a raw fleece from a shepherd, you are helping them offset the cost of raising sheep. If that shepherd is local to you, then you're also participating in your local fibershed - building communities, building soil, building local economies - all buy buying a raw fleece. That raw fleece I bought at Estes Park? It was from a sheep raised by a high school student. She was working in the booth, and she knew her stuff! She knew the qualities of each fleece, whether it would be best for spinning or felting, and much, much more. Did I need another fleece this year? Probably not. But I did fall in love with the fleeces she showed me, and I wanted to encourage her to continue to raise sheep. That's just not something we can do by ordering commercially processed spinning fiber online. 7. It's Less Expensive (Sometimes) I'll be honest here, most of the fleeces I buy cost more per ounce than commercially processed fiber. What's up with that? It's because of the "wool pool," which is meant to help shepherds sell their wool clips (even low grade wool) instead of composting, burning, or throwing it away. The trouble is that the prices shepherds get in wool pools are often so low, they don't recoup the cost of shearing. Then the fiber is all tumbled together by "class," and shipped to a mill that is often overseas, processed, and shipped back. The system is a high cost to the farmers and a high cost to the environment. A fleece that costs a little bit more per pound than commercially processed fiber has a lot of value added to it. For one thing, you know your yarn is coming from one sheep that was carefully raised, rather than many nameless sheep. Often, the fleece has been coated to make your scouring, carding/combing, and spinning easier. And again, most importantly, you're helping to support a local farmer. Sometimes, a free fleece comes my way, and then the dollar cost is definitely lower. These fleeces usually require a higher investment of time and energy to get ready for spinning, but can yield some amazing results. 8. Use Breeds You Can't Find Online Sometimes, it' really hard to find certain breeds of wool online. They are less populous, and less popular, than the wools that most dyers are selling. But you might be surprised by the variety of breeds you can find in fleece form in your local area. This is a great way to sample different types of wool. 9. Amuse Your Dog (and Your Neighbors) When I scour fleece, and when I card/comb a clean fleece that still has lots of vegetable matter, I do it outside. My dog loves this, since he gets to sniff a stinky fleece, then run in circles in the backyard for hours on end. My neighbor also gets some amusement watching the dog, and I love showing her the difference between a clean and dirty fleece. I consider it a small bit of fiber education! 10. Gray Water Makes Great Fertilizer Cleaning a fleece takes a lot of water. Luckily, it doesn't all have to go to waste. I usually fill a large container with about 20-30 gallons of cold water, and soak a fleece in that for a few hours. This releases a surprising amount of dirt, including poop. Then I remove the fleece, and have water and fertilizer for my plants. Since I live in the desert, this is an important way to help conserve water and take care of my yard at the same time. Lastly... There's nothing quite like a pile of clean wool drying in the sunshine! (This is the same fiber that is pictured as a dirty fleece at the beginning of this post!)

When you're a weaver, loom waste (sometimes called "thrums") is inevitable. When the warp is tied on to the loom at the beginning and the end, those areas can't be woven. If you're planning to incorporate fringe into your project, the beginning and end can become your fringe. Even then, you usually have to cut off some part of at least one end to even things up! With my textured warp, there was a lot of loom waste. All the different warp yarns had a different amount of stretch to them, so before I tied on to the loom, I trimmed the longer bits to even things out. Then there was the fact that I had to cut the warp in half so it would fit on my loom - more places to tie on equaled more waste. At first I was disappointed because I was concerned that all that waste meant I wouldn't have as much fabric as I'd planned for. (I'm still worried about that, tbh.) But when I realized how much loom waste I had, I realized I could try something I'd been thinking about for a while. While weaving the first piece, I put all the loom waste in a bag as it got cut off. Then I spent a couple of mornings going through the pile, knotting each end together to create six balls of yarn. Why six? I stopped when it felt like I had a shuttle's worth of yarn, but in reality, each ball is really enough for two shuttles. Then I warped the loom again, this time with one type of wool yarn. Hopefully this means I won't have the same issues with excessive waste this time! The weave structure is plain weave, and there are two rows of thin yarn in between each row of thicker "waste" yarn. Initially, I'd planned to leave all the ends hanging out of the fabric like faux fur, but decided it looked too busy, so all the ends are woven in as I go. The weaving process is really enjoyable, and I can't wait to see what this fabric is like once it comes off the loom!

If you're looking for more ideas for what to do with waste yarn, check out my Pinterest board here - it's not just for weaving! There are ideas for knitters, spinners, crocheters, and sewers too! |

Archives

January 2024

Categories

All

This website uses marketing and tracking technologies. Opting out of this will opt you out of all cookies, except for those needed to run the website. Note that some products may not work as well without tracking cookies. Opt Out of Cookies |

RSS Feed

RSS Feed